Sanitary butterfly valves are a type of valve that is used to control the flow of fluids in aseptic processing applications. Aseptic processing is a type of processing that is used to produce sterile products, such as food and pharmaceuticals. Sanitary butterfly valves are designed to prevent the contamination of products by bacteria and other microorganisms.

Benefits of Using Sanitary Butterfly Valves in Aseptic Processing

There are a number of benefits to using sanitary butterfly valves in aseptic processing applications, including:

- Sanitary design: Sanitary butterfly valves are designed to prevent the buildup of bacteria and other microorganisms. They have a smooth, polished surface without any crevices or cavities where contaminants can accumulate.

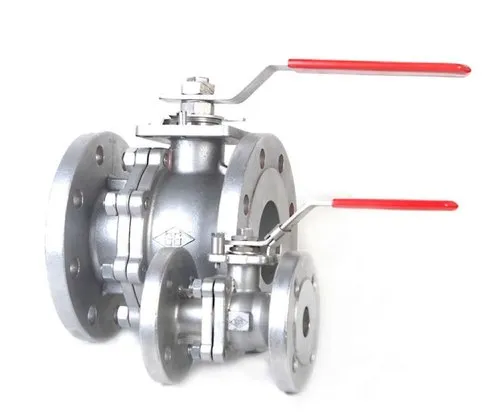

- Easy to clean and sanitize: Air Actuated All Stainless Sanitary Ball Valves are relatively easy to clean and sanitize. They can be disassembled and cleaned easily, and the seals can be replaced quickly and easily.

- Reliable: Sanitary butterfly valves are very reliable and can be counted on to operate consistently.

- Durable: Sanitary butterfly valves are made of durable materials, such as stainless steel, which makes them resistant to corrosion and wear.

Applications of Sanitary Butterfly Valves in Aseptic Processing

Sanitary butterfly valves are used in a variety of aseptic processing applications, including:

- Food and beverage processing: Sanitary butterfly valves are used in food and beverage processing to control the flow of sterile fluids such as milk, juice, and beer. They are also used to isolate equipment for cleaning and sanitation.

- Pharmaceutical processing: Sanitary butterfly valves are used in pharmaceutical processing to control the flow of sterile fluids such as drugs and vaccines. They are also used to isolate equipment for cleaning and sanitation.

- Biotechnology processing: Sanitary butterfly valves are used in biotechnology processing to control the flow of sterile fluids such as cell cultures and proteins. They are also used to isolate equipment for cleaning and sanitation.

Choosing the Right Sanitary Butterfly Valve for Your Aseptic Processing Application

When choosing a sanitary butterfly valve for your aseptic processing application, there are a number of factors to consider, including:

- Size: The size of the valve will depend on the flow rate of the fluid that you need to control.

- Material: The valve should be made of a material that is resistant to the fluids that you will be controlling. Stainless steel is a good choice for most aseptic processing applications.

- End connections: The valve should have end connections that are compatible with your piping system.

- Design: The valve should have a sanitary design that will prevent the buildup of bacteria and other contaminants.

- Features: Some sanitary butterfly valves have additional features, such as actuators and position sensors. Consider which features are important to you when choosing a valve.

Conclusion

Sanitary butterfly valves are a versatile and reliable type of valve that is ideal for aseptic processing applications. When choosing a sanitary butterfly valve for your application, be sure to consider the size, material, end connections, design, and features that are important to you.